Round Lifting Sling: The Complete Guide to Safe and Efficient Load Handling

What Is a Round Lifting Sling?

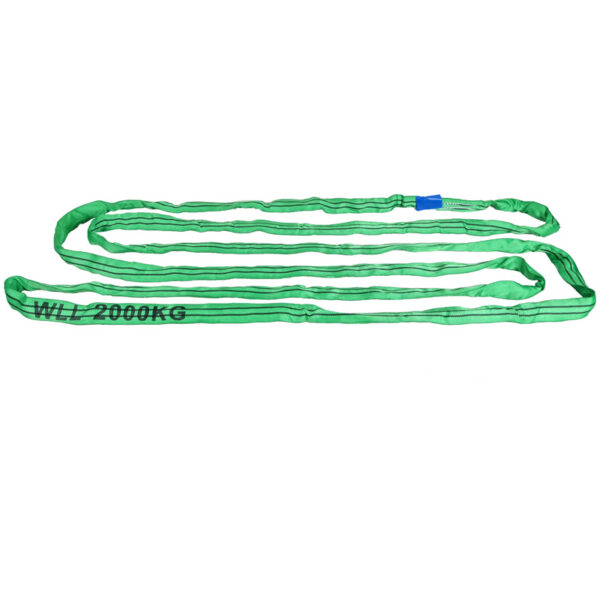

A Round Lifting Sling is a heavy-duty rigging tool designed for secure and balanced lifting of various loads. Constructed from high-performance synthetic materials like polyester, nylon, or high-performance fibers (HMPE/Dyneema), these slings provide superior strength while remaining lightweight and flexible.

Key Features:

✔ High Load Capacity – Engineered for heavy lifting with precise Working Load Limits (WLL).

✔ Flexible & Adaptable – Conforms to load shapes for better grip and stability.

✔ Durable & Resistant – Resists abrasion, UV rays, chemicals, and extreme temperatures.

✔ Non-Marring – Protects delicate surfaces from scratches and dents.

✔ Multiple Configurations – Suitable for vertical, choker, basket, and multi-leg lifts.

Types of Round Lifting Slings

1. Polyester Round Slings

- Best for: General lifting, construction, and manufacturing.

- Advantages: UV-resistant, cost-effective, and strong.

2. Nylon Round Slings

- Best for: Heavy loads with some stretch for shock absorption.

- Advantages: High elasticity, good for dynamic loads.

3. High-Performance Fiber Slings (Dyneema/HMPE)

- Best for: Extreme conditions, offshore, and chemical environments.

- Advantages: Lightweight, ultra-strong, and resistant to harsh elements.

Why Use a Round Lifting Sling?

✅ Safer than Chains & Wire Ropes – No sharp edges, reducing injury risks.

✅ Lighter & Easier to Handle – Reduces worker fatigue compared to metal slings.

✅ Versatile Applications – Ideal for construction, shipbuilding, oil & gas, logistics, and material handling.

✅ Longer Lifespan – Synthetic fibers last longer with proper care than rust-prone metal slings.

How to Choose the Right Round Lifting Sling?

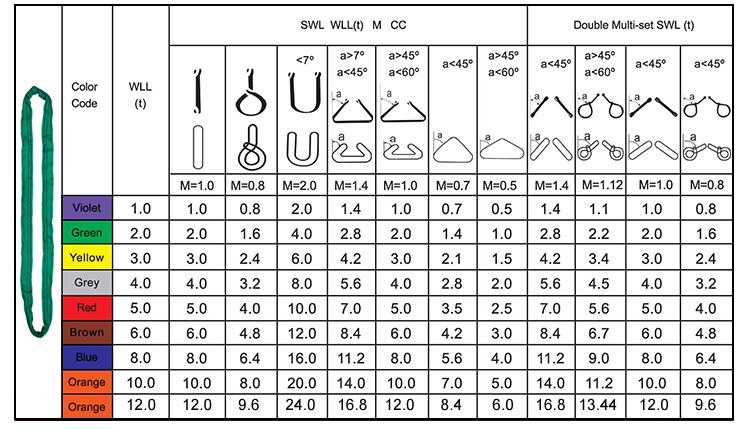

1. Determine Load Weight & WLL

- Always check the Working Load Limit (WLL) based on sling angle (e.g., choker hitch reduces capacity).

2. Select the Right Material

- Polyester – Best for general use.

- Nylon – Best for shock absorption.

- Dyneema/HMPE – Best for extreme conditions.

3. Choose the Correct Length & Diameter

- Longer slings for wider loads, thicker slings for heavier weights.

4. Check Safety Certifications

- Look for ASME B30.9, EN 1492-1, or OSHA-compliant slings.

Proper Use & Safety Tips

✔ Inspect Before Every Use – Check for cuts, fraying, or chemical damage.

✔ Use Edge Protectors – Prevent sling damage from sharp edges.

✔ Store Properly – Keep in a dry, UV-protected area away from chemicals.

✔ Never Overload – Always stay within the WLL.

🚨 Common Mistakes to Avoid:

- Using damaged or worn slings.

- Incorrect hitch selection (e.g., using a choker hitch at the wrong angle).

- Lifting unbalanced or unstable loads.

Round Lifting Sling vs. Other Slings

| Feature | Round Sling | Wire Rope | Chain Sling | Flat Webbing |

|---|---|---|---|---|

| Weight | Light ✅ | Heavy ❌ | Heavy ❌ | Light ✅ |

| Flexibility | High ✅ | Low ❌ | Low ❌ | Moderate |

| Load Protection | Excellent ✅ | Poor ❌ | Poor ❌ | Good ✅ |

| Corrosion Resistance | High ✅ | Moderate ❌ | Low ❌ | High ✅ |

| Best For | Versatile lifting | Extreme abrasion | High-heat environments | Light-duty loads |

Conclusion: The Best Lifting Solution for Safety & Efficiency

Round lifting slings offer superior strength, flexibility, and safety compared to traditional wire ropes and chains. Whether you’re in construction, logistics, or heavy industry, choosing the right round sling ensures efficient, damage-free lifting operations.

🔗 Looking for high-quality round slings? Always buy from certified manufacturers and follow OSHA/ASME standards for maximum safety.